one of the most trusted

jewellery manufacturing

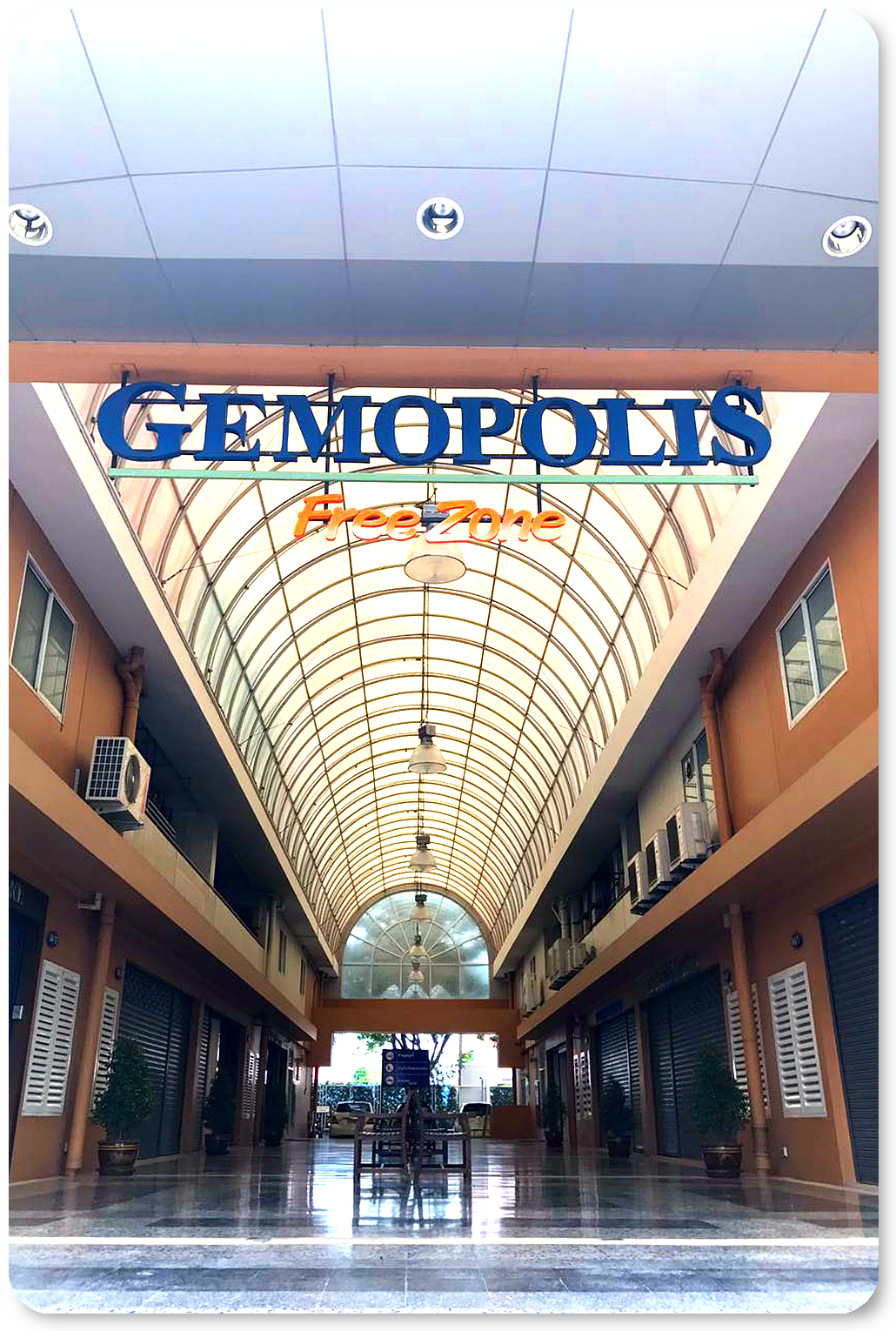

LOCATED IN THAILAND

how it work

Palaces Factory is your ultimate one-stop destination for all your jewelry manufacturing needs. Whether you're looking for an OEM or ODM manufacturer, we guide you through every step of the process. From initial SKETCH DESIGNS to expertly crafted pieces, we ensure elegance and confidence in every creation.

We go beyond expectations by delivering INNOVATIVE SOLUTIONS tailored to any demand. By staying ahead of emerging trends and market needs, we continuously refine our craftsmanship to create exceptional jewelry. Our seamless blend of technical expertise and creative vision ensures that every piece meets the highest standards of quality, elegance, and distinction.

Our team of skilled artisans is dedicated to transforming your vision into reality, crafting each piece with precision, care, and exceptional attention to detail. We ensure that every step of the JEWELLERY MAKING PROCESS meets our highest quality standards, bringing your unique ideas to life with elegance and excellence.

about

palaces factory

Established in 2013, Palace Factory is one of a leading jewelry manufacturer based in Bangkok, Thailand. Our state-of-the-art facility, designed with transparency in mind, integrates precision and cutting-edge technology at every stage of production.

With over a decade of expertise, we have crafted over a million exquisite jewelry pieces, meticulously setting diamonds and gemstones with unmatched accuracy. Our blend of advanced technology and traditional artistry ensures high-end, intricate designs that cater to discerning tastes.

Committed to excellence, we continue to set new standards in the fine jewelry industry.

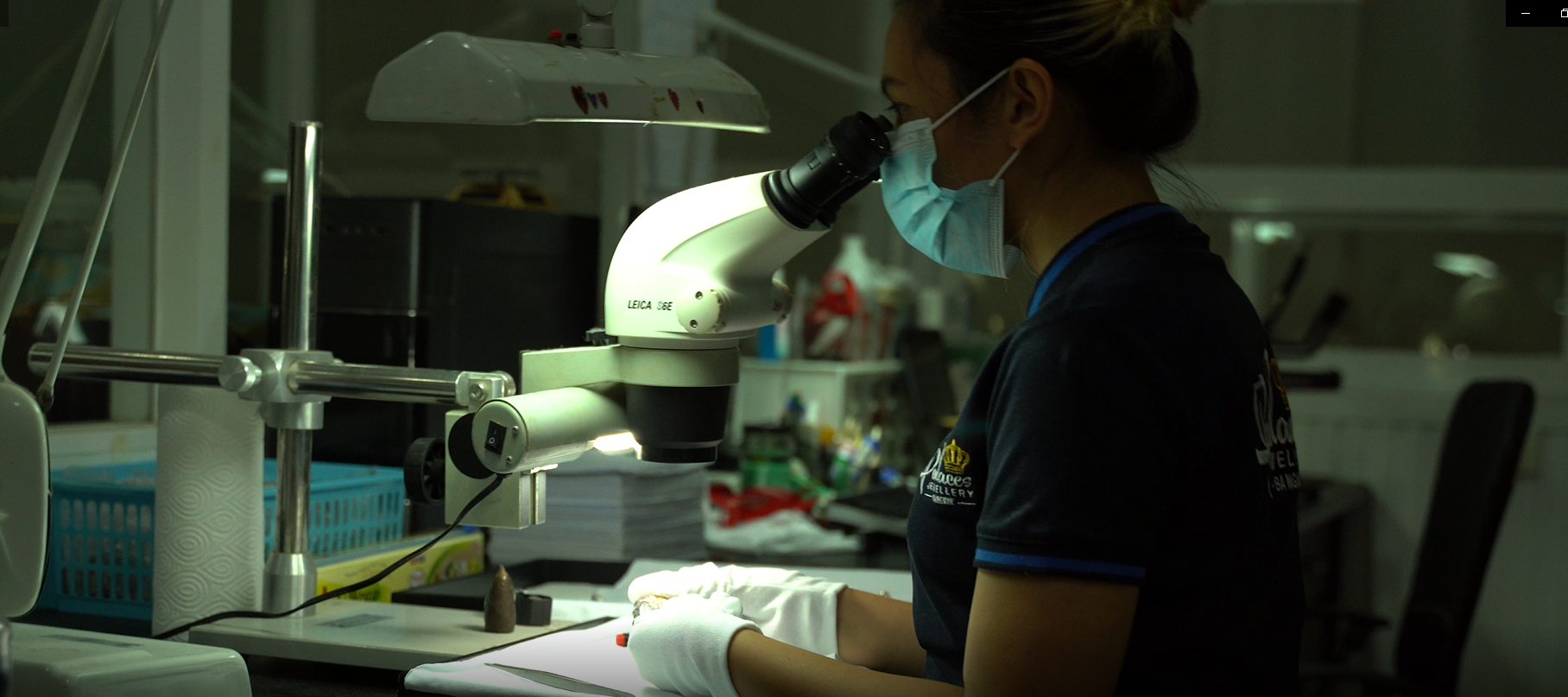

Craftmanship

With unwavering dedication to craftsmanship, each jewelry piece is meticulously designed and expertly crafted, blending precision, artistry, and the finest materials. Combining traditional expertise with cutting-edge technology, we create timeless masterpieces that exude sophistication, elegance, and lasting beauty.

Precision

Precision is at the heart of our craftsmanship, where every cut, setting, and finish is executed with absolute accuracy through a seamless blend of advanced technology, meticulous attention to detail, and time-honored techniques, ensuring each jewelry piece radiates unparalleled beauty, durability, and timeless perfection.

Innovation

At the heart of our craftsmanship is our innovation, where tradition meets technology to create exceptional jewelry. Through our expert artistry, precision in designing, and the finest materials, we craft pieces that redefine elegance, push boundaries, and set new standards in luxury jewelry and design industry.

our machineries

what make us qualified

who we are

Our mission is to establish ourselves as a leading designer, manufacturer, and supplier of exquisite jewelry by upholding the highest standards of quality and delivering exceptional service that consistently surpasses customer expectations. We are dedicated to craftsmanship, innovation, and attention to detail, ensuring that every piece we create reflects our passion for excellence.

We envision our establishment as a distinguished brand and a world-class factory at the forefront of the high-diamond jewelry industry. Our goal is to be globally recognized for our luxury offerings, superior artistry, and unwavering commitment to excellence, setting new benchmarks in the world of fine jewelry.

Our team of skilled artisans works diligently to bring your vision to life, ensuring that every piece is crafted with precision, care, and an unwavering commitment to excellence. Whether you seek a signature piece from our exclusive collection or wish to bring your own ideas to fruition through our contract manufacturing services, we uphold the highest standards of quality and craftsmanship at every stage of production.

In addition to serving individual clients, we collaborate with esteemed brands under strict Non-Disclosure Agreements (NDAs) to create exclusive collections that reflect their unique identity while maintaining the integrity of our production process. These partnerships allow us to expand our capabilities and offerings, providing an impressive range of options—from stunning gold chains and elegant diamond rings to exquisite diamond earrings and intricately designed bracelets and necklaces.

By combining artistry, innovation, and precision, we continue to redefine luxury in fine jewelry, delivering timeless creations that resonate with sophistication and style.

We are dedicated to equipping our employees with the skills, knowledge, and experience they need to thrive. By fostering a culture of continuous learning and innovation, we empower our team to adapt to industry trends and contribute to our success. Our commitment to growth ensures we remain competitive in a constantly evolving market.

To continuously improve our offerings, we invest in research and development, inspiring creativity in our designs and staying ahead of market demands. This commitment to innovation allows us to craft timeless, distinctive jewelry while setting new standards in artistry and craftsmanship.

We are deeply committed to exceeding customer expectations by providing personalized service and delivering high-quality products that reflect our dedication to excellence. Our passion for craftsmanship, precision, and innovation drives us to create jewelry that not only meets but surpasses the highest standards of quality and artistry.

Through exceptional attention to detail and a deep understanding of our clients' unique preferences, we strive to offer a truly tailored experience that fosters trust and long-lasting relationships. Every interaction with our customers is an opportunity to showcase our commitment to excellence, ensuring they feel valued and confident in their choices.

By continuously refining our designs, embracing new technologies, and upholding the integrity of our craftsmanship, we aim to set new benchmarks in the jewelry industry. Our goal is not just to provide beautiful pieces but to create meaningful, timeless treasures that resonate with our clients for years to come.

We are dedicated to expanding our global presence, ensuring that our luxury brand becomes synonymous with exceptional quality, craftsmanship, and sophistication in fine jewelry. Through strategic growth initiatives, innovative designs, and a commitment to excellence, we will strengthen our position in international markets. By continuously refining our artistry and upholding the highest standards, we aim to captivate discerning customers worldwide, solidifying our reputation as a premier name in the fine jewelry industry.

With a deep commitment to craftsmanship, precision, and innovation, we create jewelry that embodies both artistry and excellence. By seamlessly blending time-honored techniques with cutting-edge advancements, we ensure that every piece is meticulously designed and masterfully crafted to the highest standards of quality and elegance. Our dedication to perfection allows us to deliver timeless creations that reflect sophistication, innovation, and the finest level of craftsmanship in the industry.

We are committed to ethical sourcing and competitive pricing, ensuring that every material is responsibly and sustainably obtained. By partnering with trusted suppliers and upholding fair trade practices, we maintain the highest ethical standards while supporting responsible mining and fair labor conditions.

At the same time, we strive to make luxury jewelry more accessible by offering competitive pricing without compromising on quality. Through efficient sourcing and innovative production methods, we provide exquisite, high-value pieces at fair and transparent prices. By balancing ethical responsibility with affordability, we empower customers to invest in timeless jewelry that reflects both beauty and integrity.

PRODUCTION PROCESS

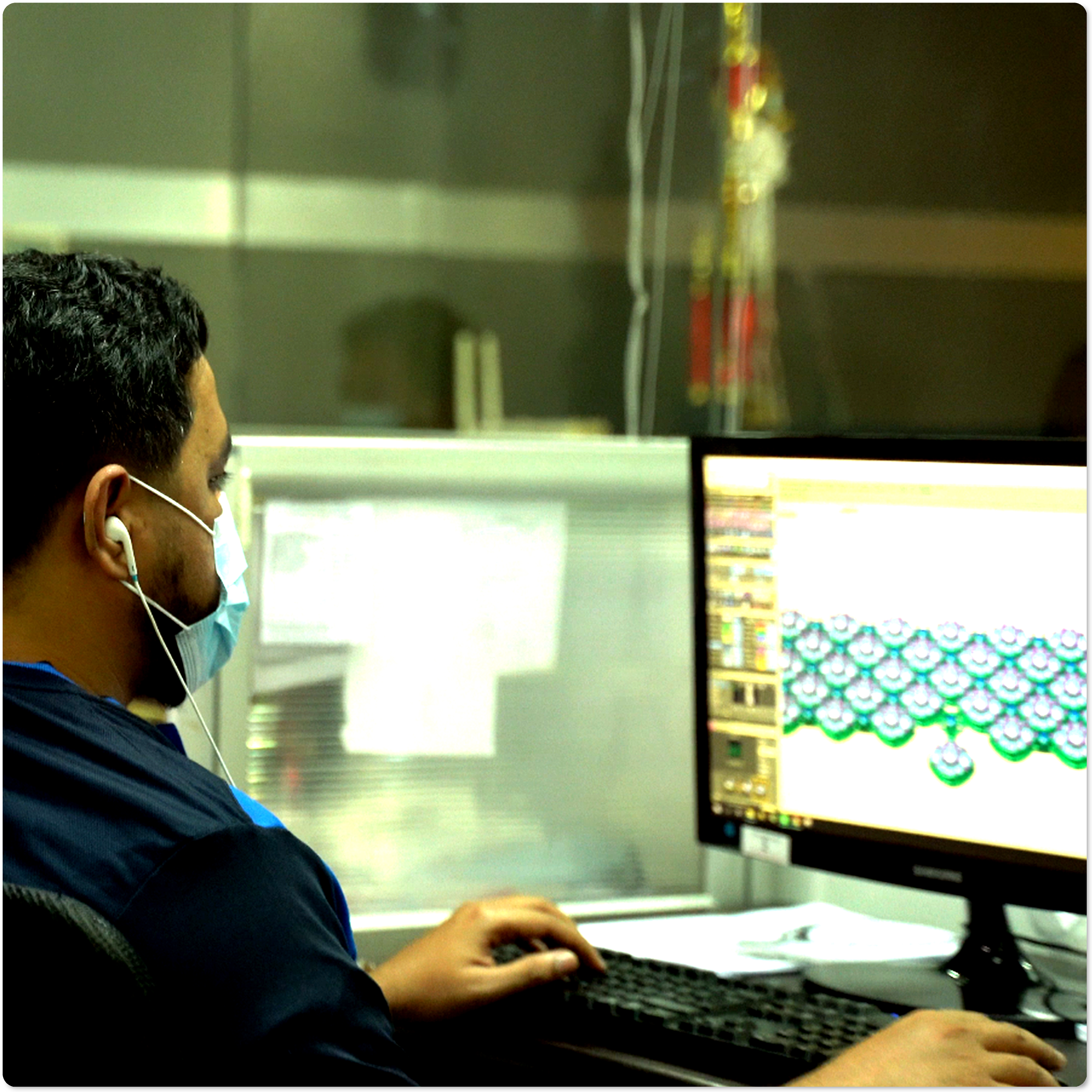

3d designing

While some artists create in studios, we craft brilliance in our factory—where creativity meets precision. Continuously pushing the boundaries of innovation, we utilize state-of-the-art jewelry design software and the expertise of our skilled professionals to transform even the most intricate ideas into stunning realities.

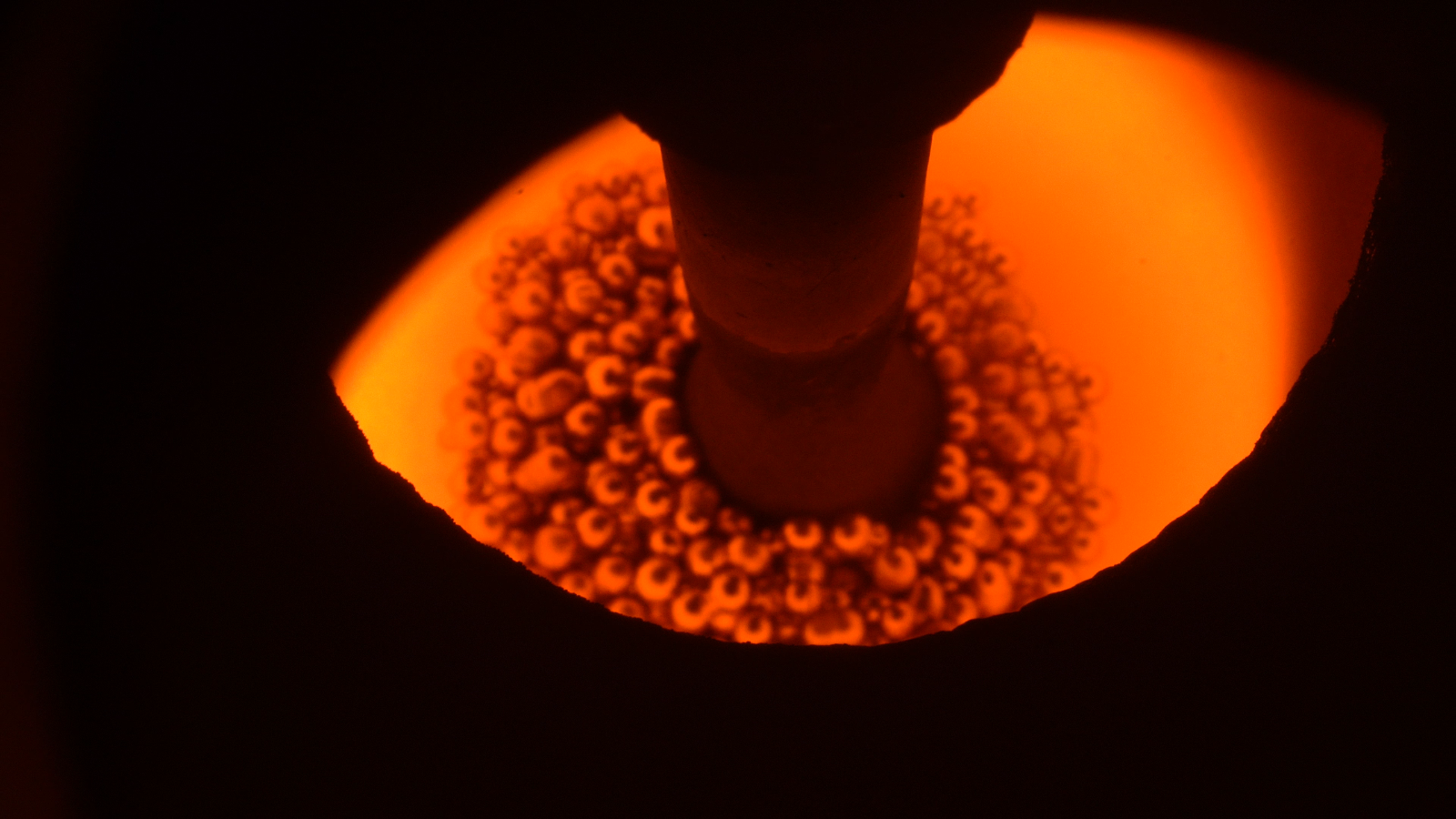

casting process

We provide premium jewelry casting services with a minimum order of 1 kilo, customized to meet customer specifications for gold mixtures ranging from 9K to 18K. Utilizing advanced melting technology, we ensure precise metal composition, delivering exceptional quality and consistency in every cast.

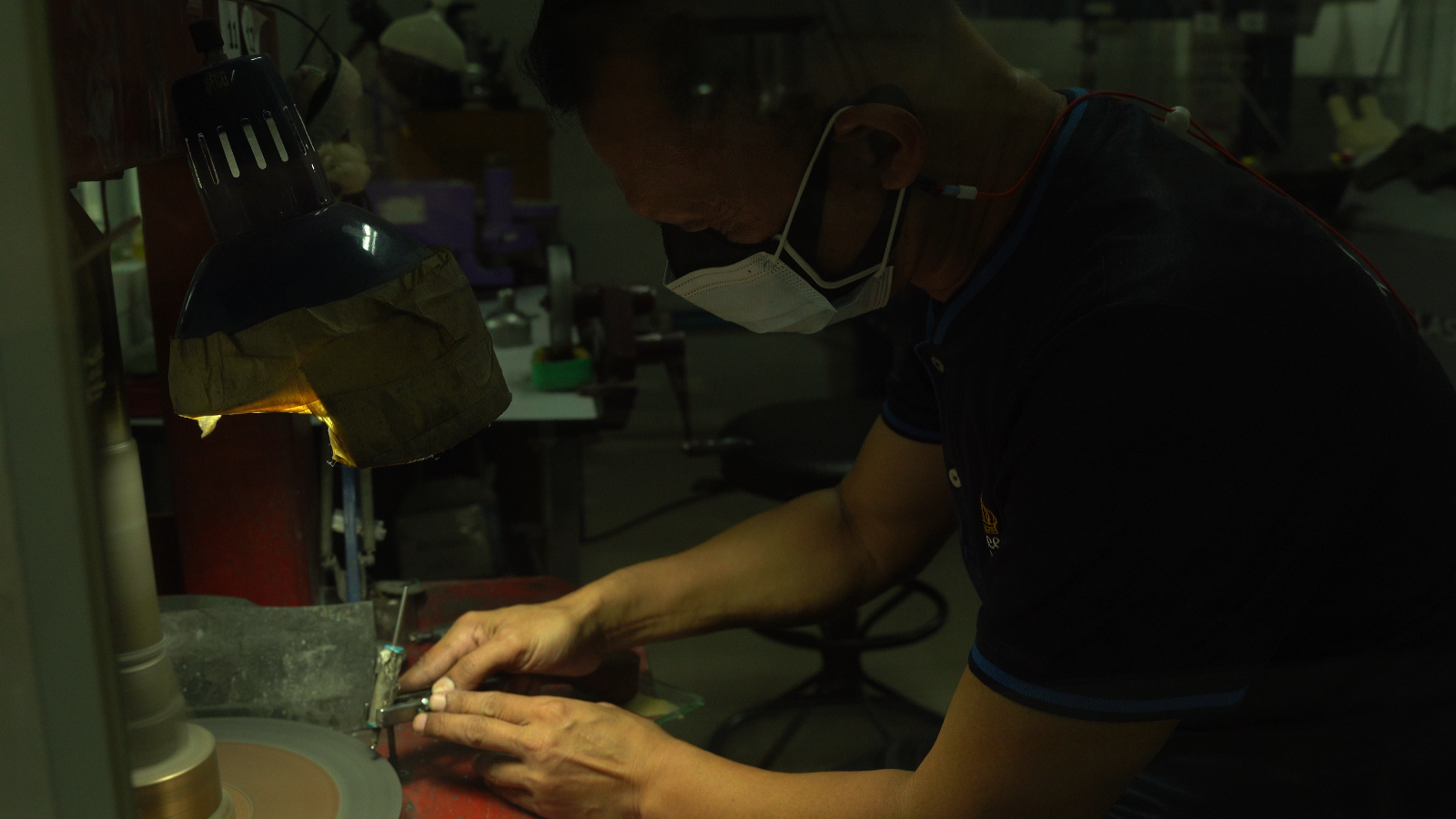

filling process

With precision and expertise, we meticulously remove blemishes from mountings after casting. Our skilled fillers excel at refining even the most intricate pieces, reaching the smallest details to ensure flawless craftsmanship.

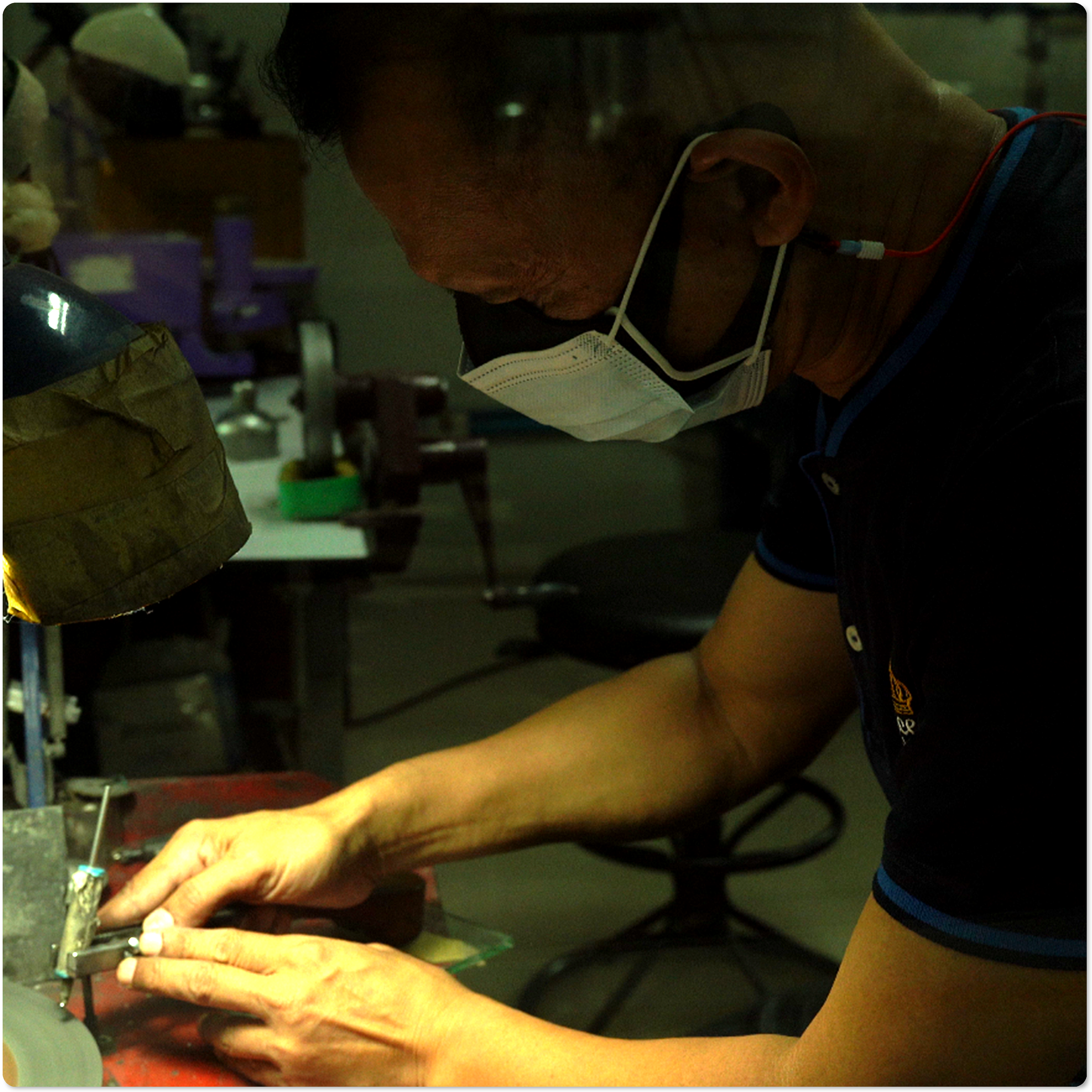

setting process

With a daily capacity of 5,000 pieces, we expertly handle diamond and stone setting with precision. Our expertise spans pavé micro-setting, traditional prong, bezel, and channel settings, as well as the most intricate and challenging invisible settings.

stone cutting process

We supply a wide range of natural diamonds and gemstones, from loose stones to certified pieces, available in various qualities, clarities, colors, and cuts. Our factory specializes not only in standard stone sizes and shapes but also offers unique, custom cutting services to create one-of-a-kind gemstone designs.

polishing process

Every piece undergoes rigorous quality control, covering final polishing, rhodium plating, and laser engraving of the requested stamp. Only after meeting our highest standards do we carefully pack and deliver it straight to the customer’s doorstep.

Contact us